What if the Wrong Spring is Loaded for a Shock Absorbing Caster?

The impact of springs on a shock absorbing caster is critical, to say the least. The springs determine how the caster will perform and how much load it can carry. Some may think, it is best to use a spring that is rated to carry significantly more than the specified load, in actuality that would cause greater vibration. If the spring is rated to carry less than the specified load, it could essentially eliminate the benefits of a shock absorption.

Now imagine you are the cart operator and you are pushing a cart that is loaded beyond its rated spring capacity. Naturally, you are expecting the caster to absorb the shock when encountering an obstruction such as a crack in the floor, unfortunately, the springs cannot support the load and the cart comes to screeching halt. The contents of the cart go tumbling over, onto the ground, and the operator risks straining there muscles, because they tried to push harder to get over the obstruction. This is just one example of a situation where the wrong spring is used on a shock absorbing caster.

In order to determine the right shock absorbing caster, and the right springs for that caster, the following need be evaluated:

- Weight of the cart empty

- Weight of the load

- Will there be thrust loading

- Speed

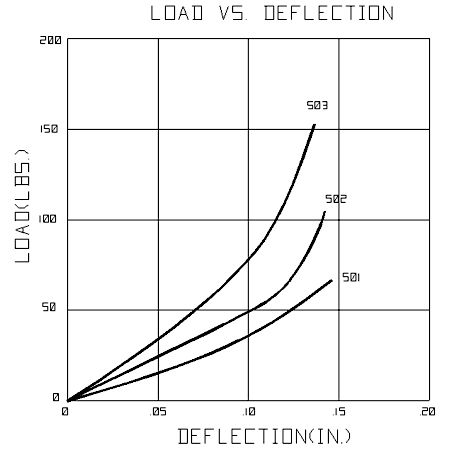

These factors are taken into consideration, and utilized to determine the right caster and the right springs for that caster. Calculations are performed to determine the proper “Spring Constant” (how much force the spring exerts when pressure is applied) for the application. The proper spring dramatically reduces, if not completely eliminates shimmy, resonance and dynamic bounce.

Given that these are springs, they have a non-linear deflection rate, meaning that there is not a 1:1 ratio between amount of force applied and deflection of the springs. Therefore, there is a “sweet spot” where the springs will perform best, yet there is still some additional capacity if needed. The amount of additional capacity varies by the application. For Modern Suspension Systems Casters, the goal is to achieve 50% greater capacity. It is not recommended to consistently load the carts beyond the capacity, but if for some reason you have an occasional incident that requires it, it is good to know that the load will be supported and the shock absorbing functionality will exist.

To learn more about Modern Suspension System Casters and the right shock absorbing caster for your application, please contact us at customercentral@casterconcepts.com